As a global manufacturer of Automotive connectors, our focus is on the implementation of customer-specific solutions in compliance with the highest quality and environmental standards in accordance with IATF 16949:2016 (automotive industry) and ISO 14001:2015 (environment). Having more than 60 years of experience in connectors, with worldwide manufacturing and engineering facilities, KYOCERA AVX is not only supplying standard off-the-shelf connectors within the automotive industry. For effective communication within complex electric systems in vehicles, we are faced with a growing importance of customized connectors. Our portfolio ranges from simple airbag housings for engine control unit functions up to complex mechatronic solutions for electric vehicles or autonomous driving.

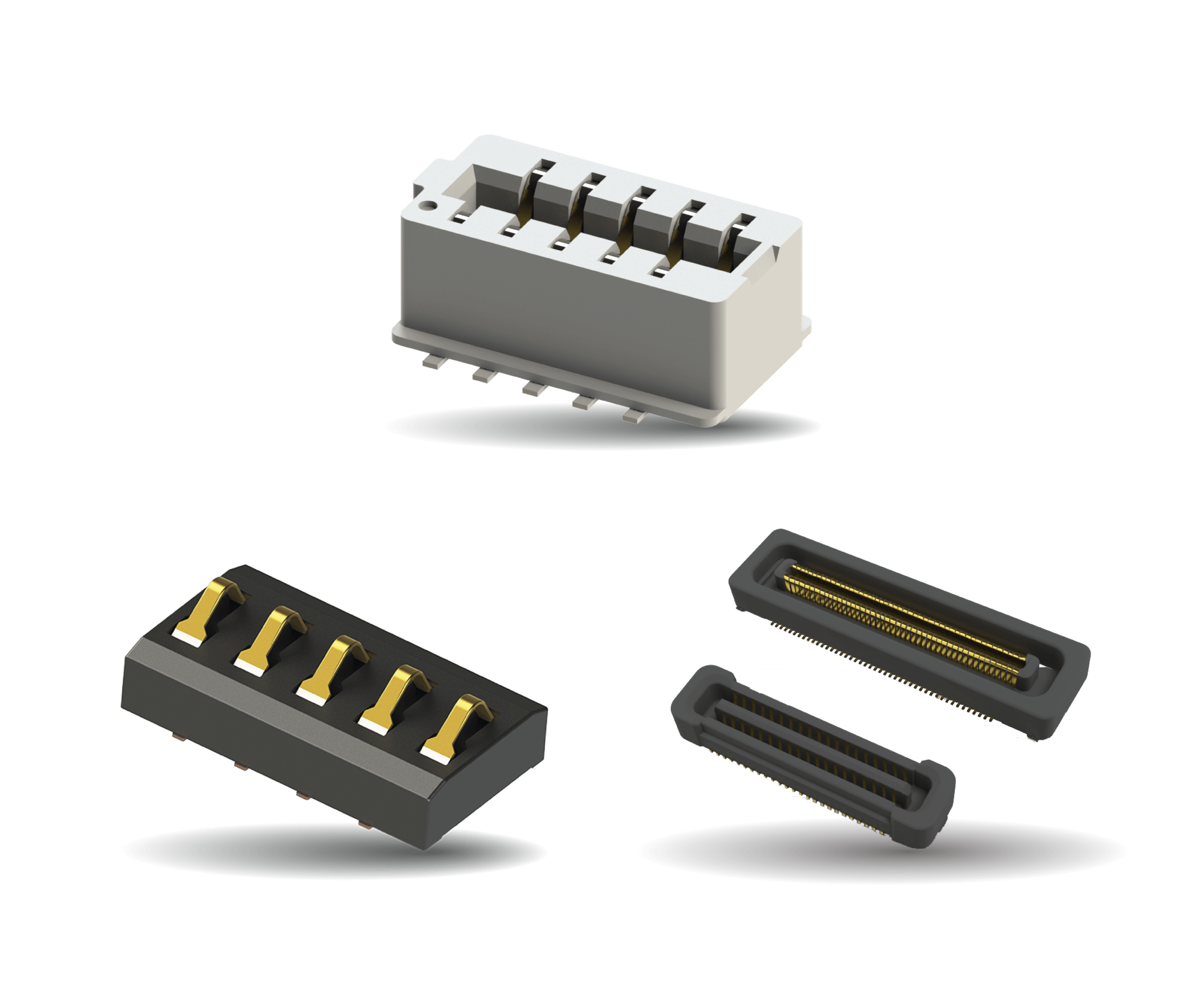

PRODUCTS

CUSTOM AUTOMOTIVE

With its customized automotive branch KYOCERA AVX is supplying since decades solutions from product development until mass production in multi million pieces, everything customized from production cell up to packaging.

From manufacturing side KYOCERA AVX offers a full vertical integration, with own contact stamping and plating, molding, assembly and stitching processes. With these in-house capabilities, KYOCERA AVX covers the whole process from automation concept planning to set-up of complete production cells.

Our automotive customer base is formed by OEM’s and TIER1’s around the globe to whom we are offering engineering services as well such as R&D for stamping and mold tools, simulations like mold flow analysis, prototyping and product/process layout.

With development of stamping tools KYOCERA AVX starts the vertical integration within the manufacturing process. Several facilities globally ensure to produce highest demands in quantity and quality of stamped contacts. As following process step KYOCERA AVX is operating multiple plating lines offering all for automotive relevant plating options in highest quality. Just as individual as KYOCERA AVX’s customized connector products, is the production behind via semi- or full-automation processes. All process steps are combined in a production cell, including individual contact feeding system, molding/overmolding process, assembly of additional components (bushings, capacitors, sealings, etc.), labeling, testing systems and final packaging in customized trays/boxes. Especially for high pin count connectors KYOCERA AVX operates multiple high performance stitching machines equipped for different tasks like different contact bending and multiple contact types in one process run.

In addition, KYOCERA AVX performs multiple supporting processes coming along with vast customized product portfolio. For sealing of a housing different solutions can be offered from simple hand assembly of a gasket up to full-automatic 2-component molding process. In regards of welding different processes like laser-, resistance- or ultrasonic-welding can be offered. Venting/pressure balance membranes can be glued in, stitched or be welded by ultrasonic process.

PROCESSES & TECHNOLOGY – PRESSFIT & IDC

In solderless Pressfit and IDC technologies, the joining mechanism is cold welding. The cold weld has been the baseline contact method for high-quality and high-reliability connections for nearly a century. With Varipin KYOCERA AVX offers pressfit pin contact technology, which provides a robust connection between a printed circuit board (PCB) and a pin.

Pressfit

The Press-fit connection is a connection technology between PCB and a pin. This solderless process provides a gas tight connection of the connector pin within the plated through hole in the PCB.

- The main advantages of press-fit technology are:

- Only One Step Process

- 100% Lead-Free Possible

- No Rework Necessary (No Welding Bridges or Solder Beads)

- No Additional Thermal Loading of Board

- No Remaining Residue from Flux Process

- Stable Electrical Contact with High Reliability (Cold Welding Connection)

KYOCERA AVX industry proven contact technology offering, Compliant or Press-fit Pin PCB termination, was developed and patented in the 1970’s.

KYOCERA AVX Varipin® flexible pressfit pin is used in Automotive products for more than 25 years. The breadth of our automotive qualified pin range provides design flexibilities based on hole size, PCB thickness, operating temperature ranges, current carrying capabilities, and more.

- Special needle eye geometry

- Various raw material and plating

- Up to 150°C

- 0.4 to 1.2mm band thickness

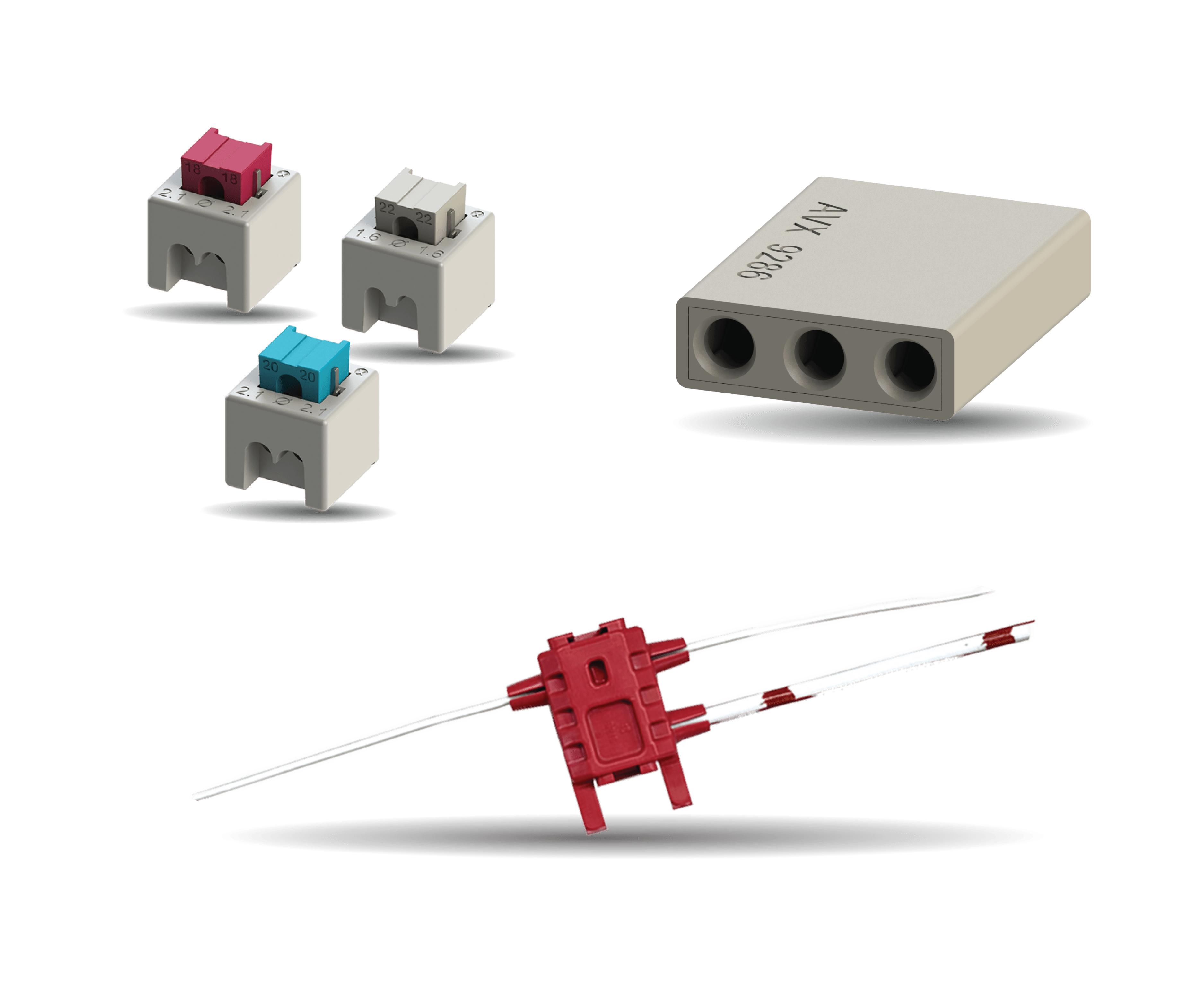

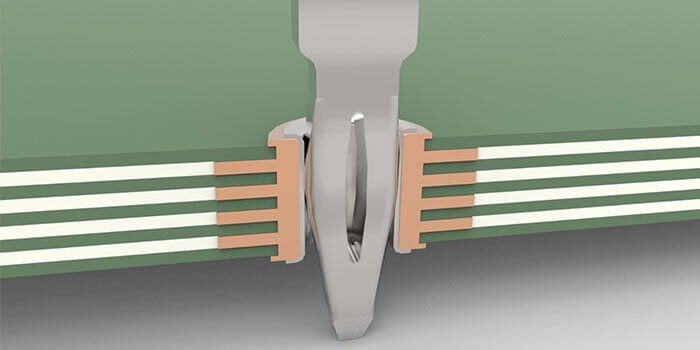

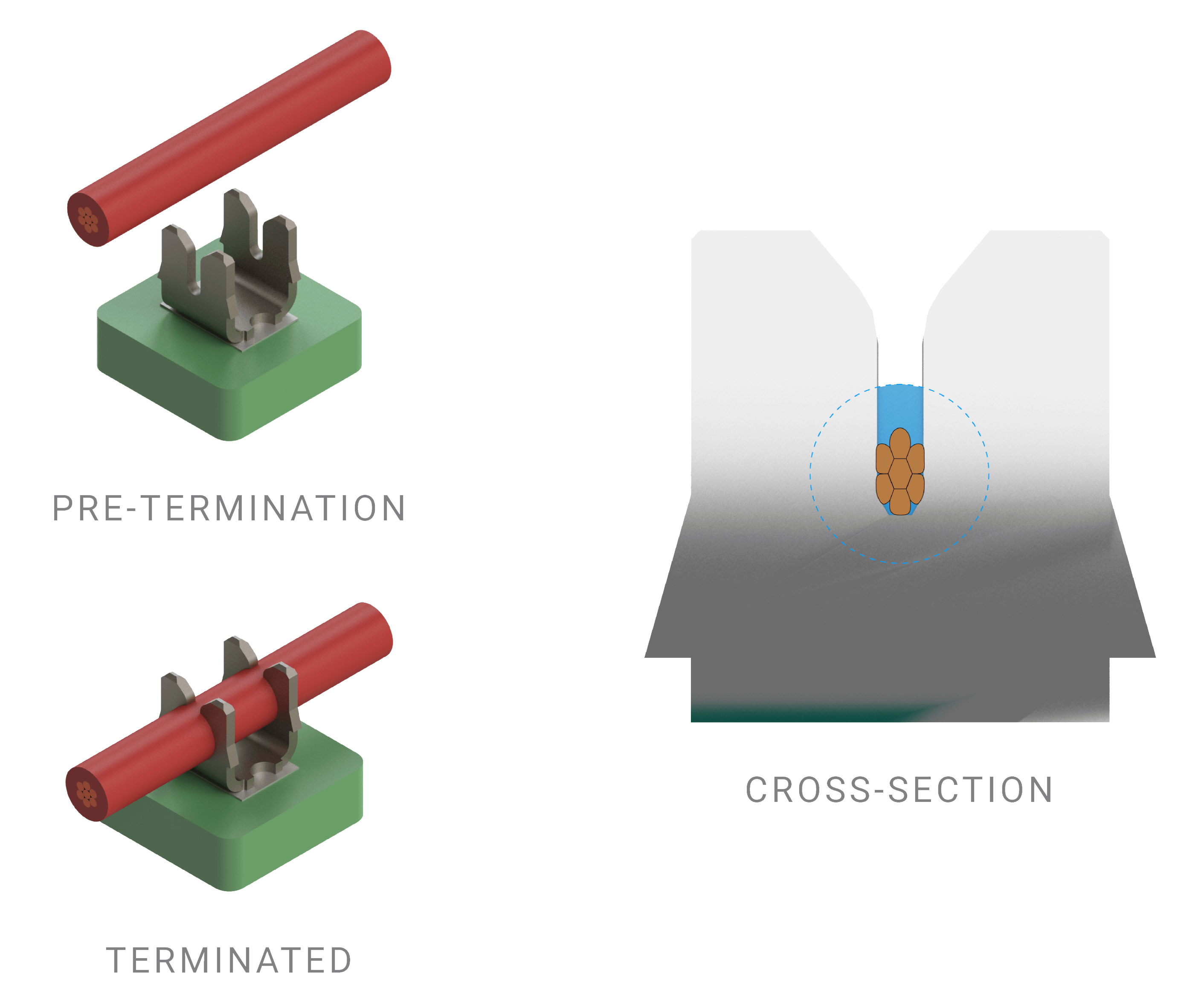

IDC (Insulation Displacement Connection)

IDC technology is commonly used solderless principle to connect a wire (or the lead of an electronics component such as a capacitor). The principle of cold welding is conceptually quite simple: in a vacuum, two pieces of similar metals will simply join when placed in close proximity. Assuming a clean surface and no oxidation or corrosion, the two metal pieces simply lose any boundary to define where one ends and the other begins. To achieve this same phenomenon in open air, the gas between the two pieces of metal must be forced out. In an IDC connection, a wedge-shaped slot is forced through the wire in such a way as to guide the metal wire into the slot. The wedge shape exerts a spring force on the wire bundle to create the cold weld.

IDC based connectors make use of this across a myriad of automotive and other transportation sector applications. IDC connectors, for their manufacturing simplicity and low cost, are taking center stage, especially as power requirements and highspeed data requirements evolve in modern vehicles. KYOCERA AVX has been a leader in this space for over three decades and is well-positioned to offer automotive connectors solutions for the long term.

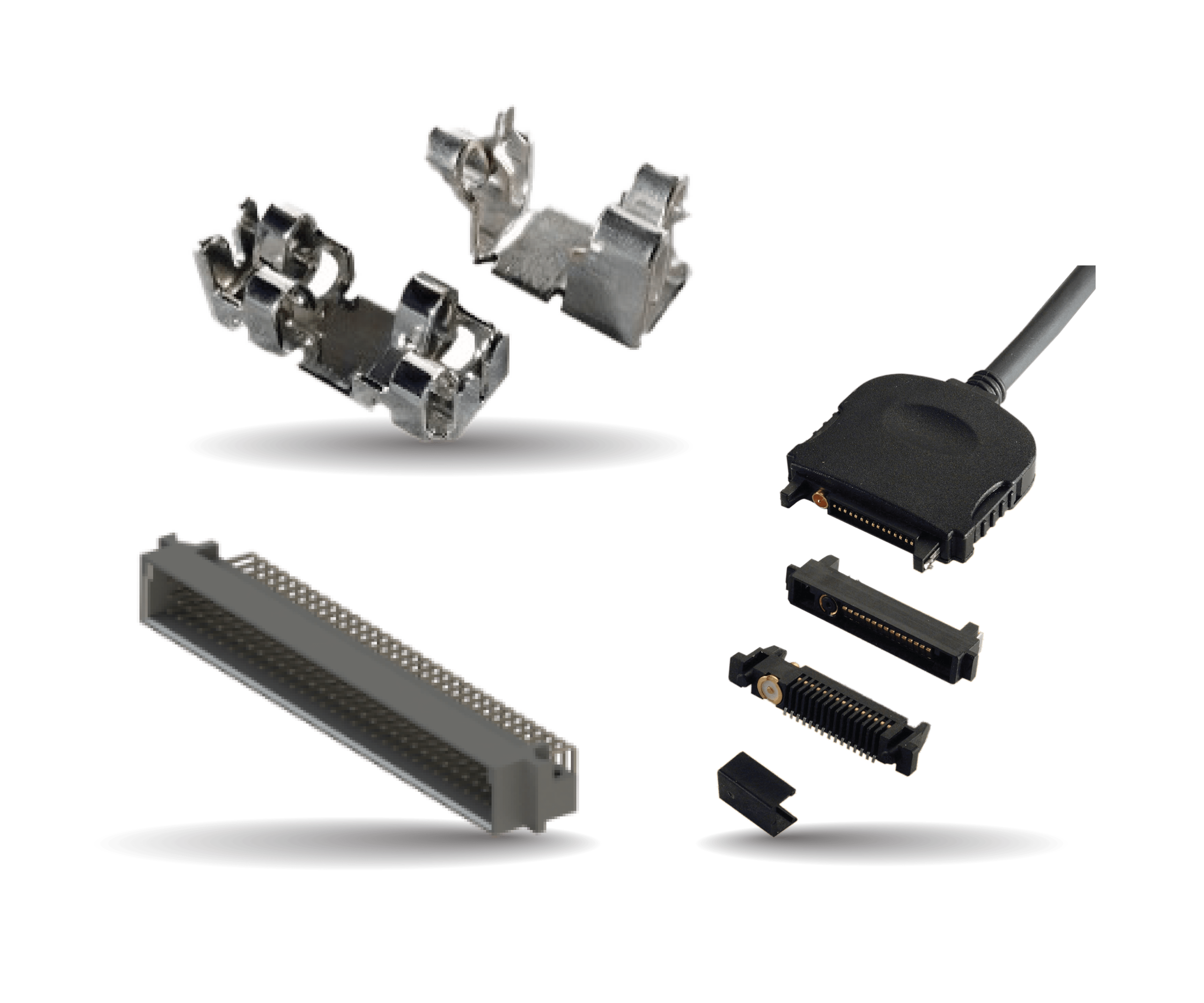

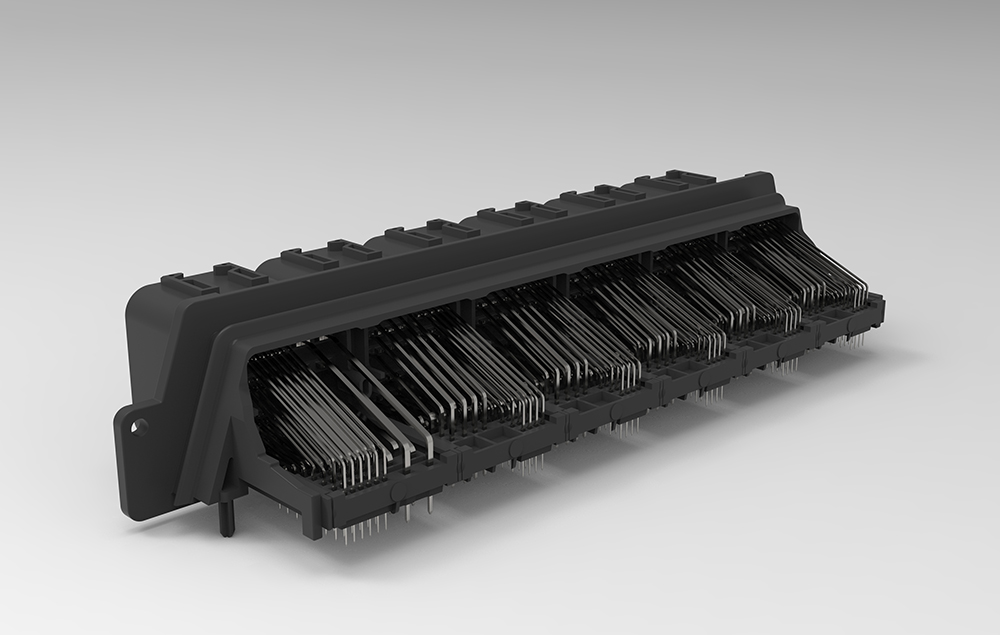

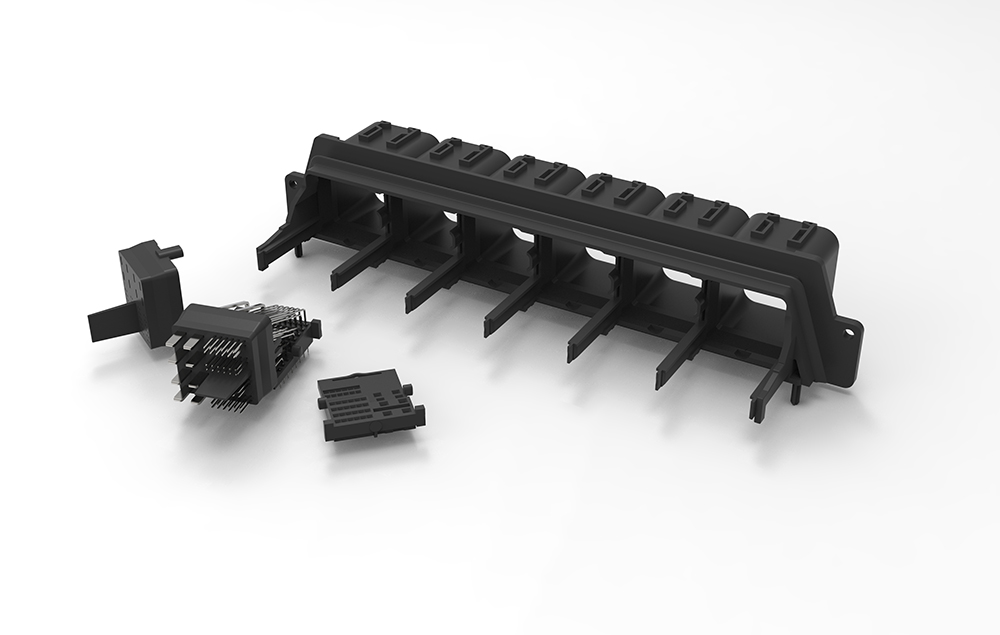

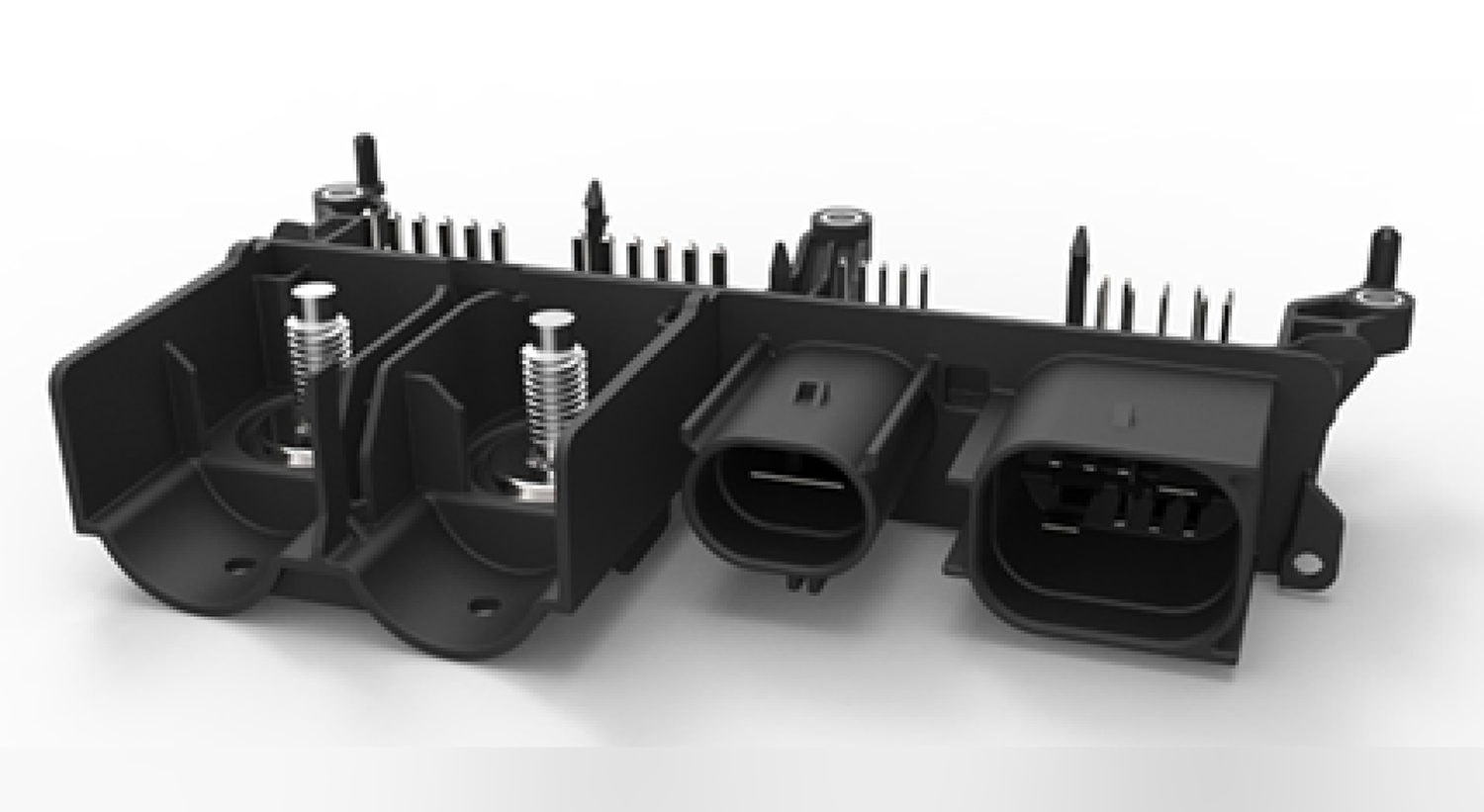

High Pin Count Connectors

Since early days of manifold injection and digital engine management system, engine control units pin counts never stopped growing, driven by introduction of new functions, controllers and sensor to cope with vehicles emissions regulations and lower fuel consumption. Due to limited space in the engines compartments, new design and manufacturing challenges have raised to accommodate higher pin density (200+), smaller sizes, precise position and outstanding reliability expectation of the automotive market.

High pin counts connector are now used on wide range of Control Unit such as safety functions (Airbag, ABS/ESP…)

- Following customer design, KYOCERA AVX can offer:

- State of the art manufacturing solutions such as semi-auto or full auto overmolding and high speed stitching processes

- Pin thru hole (PTH) or Press fit termination for any automotive standard contact from 0.4 to 1.2mm band thickness

- Multiple plating option for both interface and PCB areas

Automotive Applications:

Engine Control Units (ECU)

Airbag Control Units (ACU)

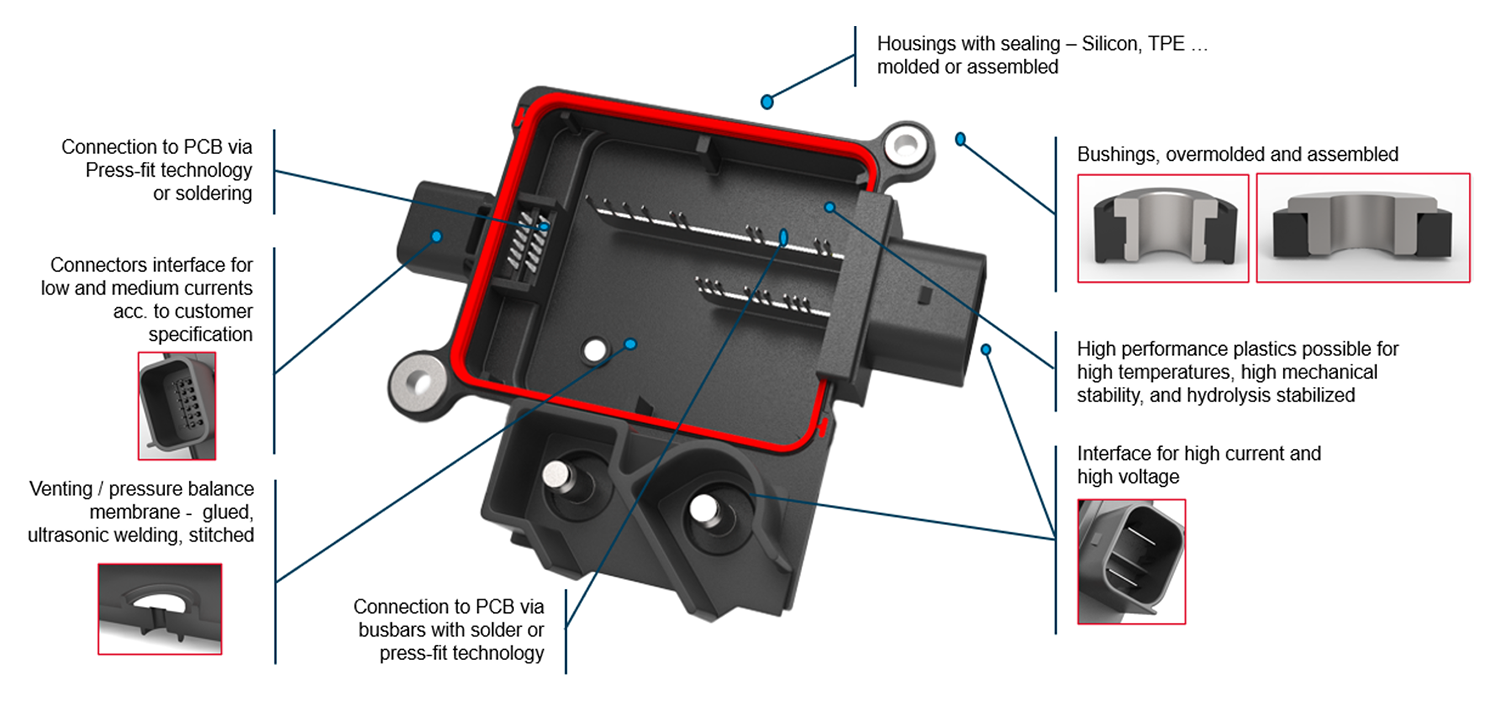

Integrated & Complex Housings

Since early days of manifold injection and digital engine management system, engine control units pin counts never stopped growing, driven by introduction of new functions, controllers and sensor to cope with vehicles emissions regulations and lower fuel consumption. Due to limited space in the engines compartments, new design and manufacturing challenges have raised to accommodate higher pin density (200+), smaller sizes, precise position and outstanding reliability expectation of the automotive market.

- Multiple stamping and plating options

- Molded gaskets (2 component molding)

- Integration of electric components

- Diverse potting technologies

- Insert of venting membranes

KYOCERA AVX Products Features & Benefits:

- ADAS Sensor Housing

- Airbag Control Unit (ACU)

- Comfort Electronics

- Brake System Control Units

- Gearbox Transmission

Automotive Applications:

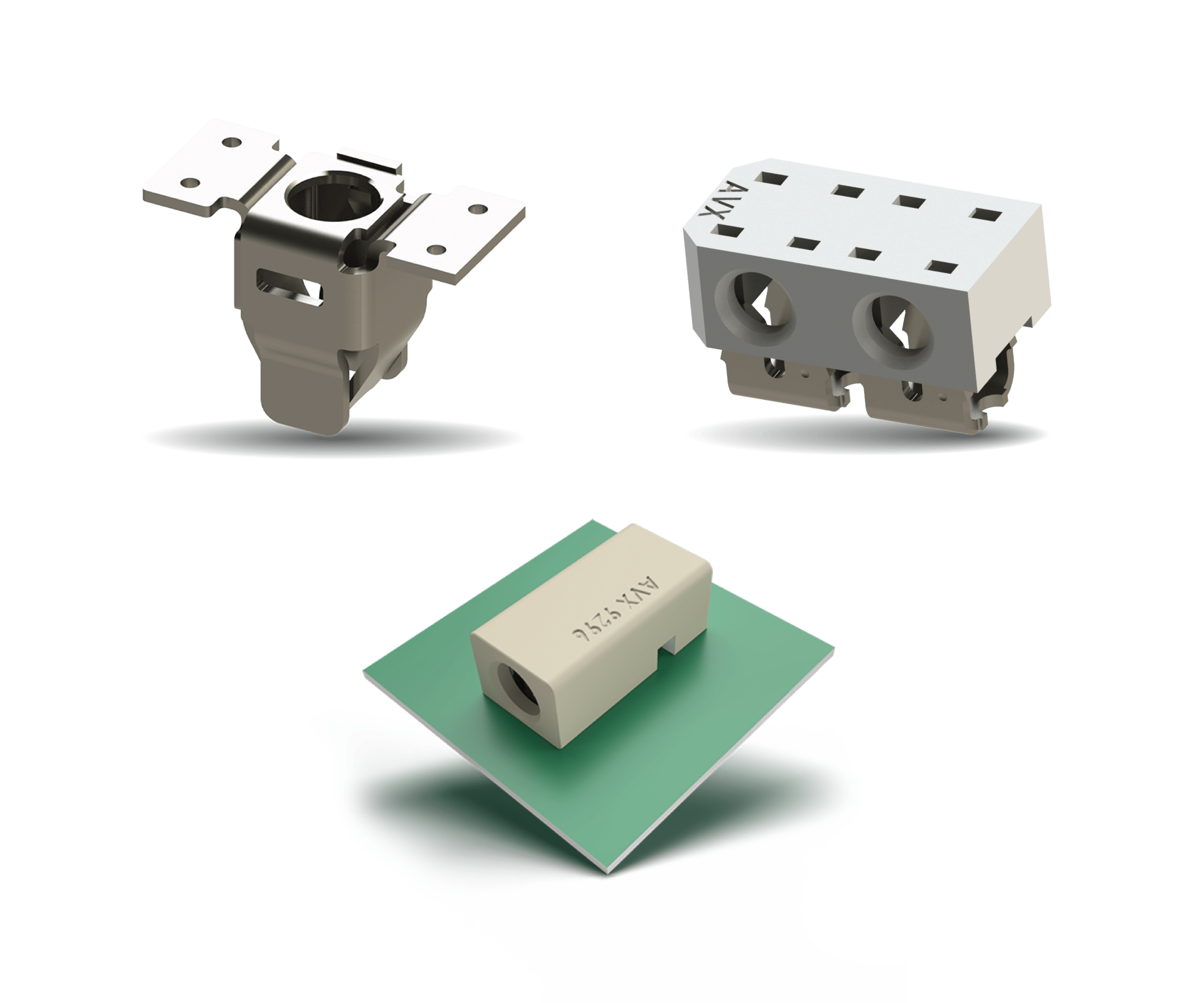

Sensor Housings

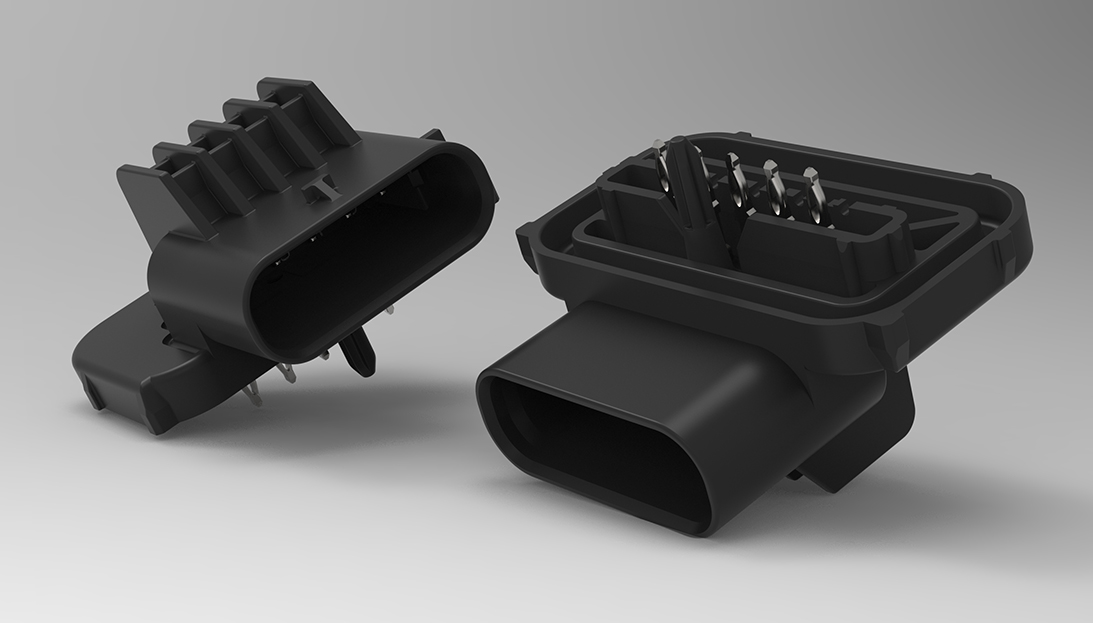

All modern vehicles come with a large variety of sensors, covering all type of applications (engine management systems, powertrain, safety, comfort electronics…) with a same goal, improve efficiency, safety and driving experience. Autonomous driving introduces further intensive usage of these components.

In order to support market demands, KYOCERA AVX has extended its production capacity and flexibility of over molding processes to cope with higher volume and multiple variants.

- Over molding

- Multiple plating option (interface & PCB)

- Flexible assembly lines

- Pressfit technology

KYOCERA AVX Products Features & Benefits:

- Distance Control

- Airbag sensor

- NOx & exhaust system sensor

Automotive Applications:

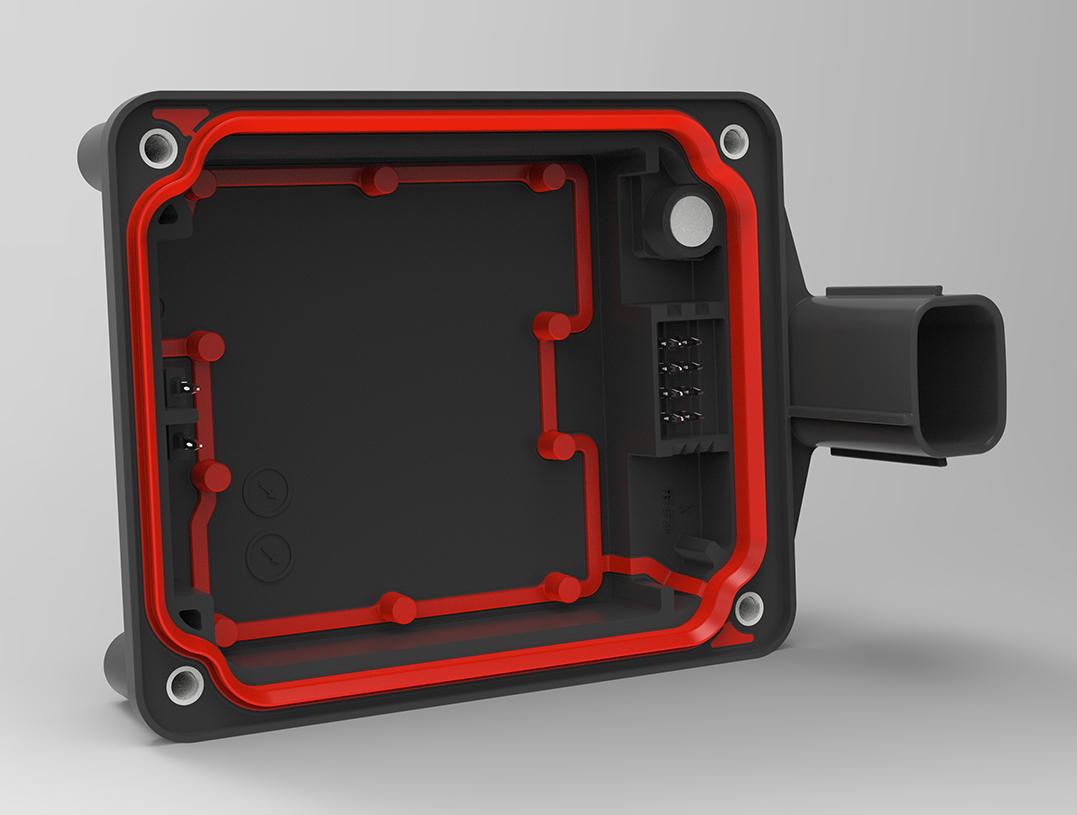

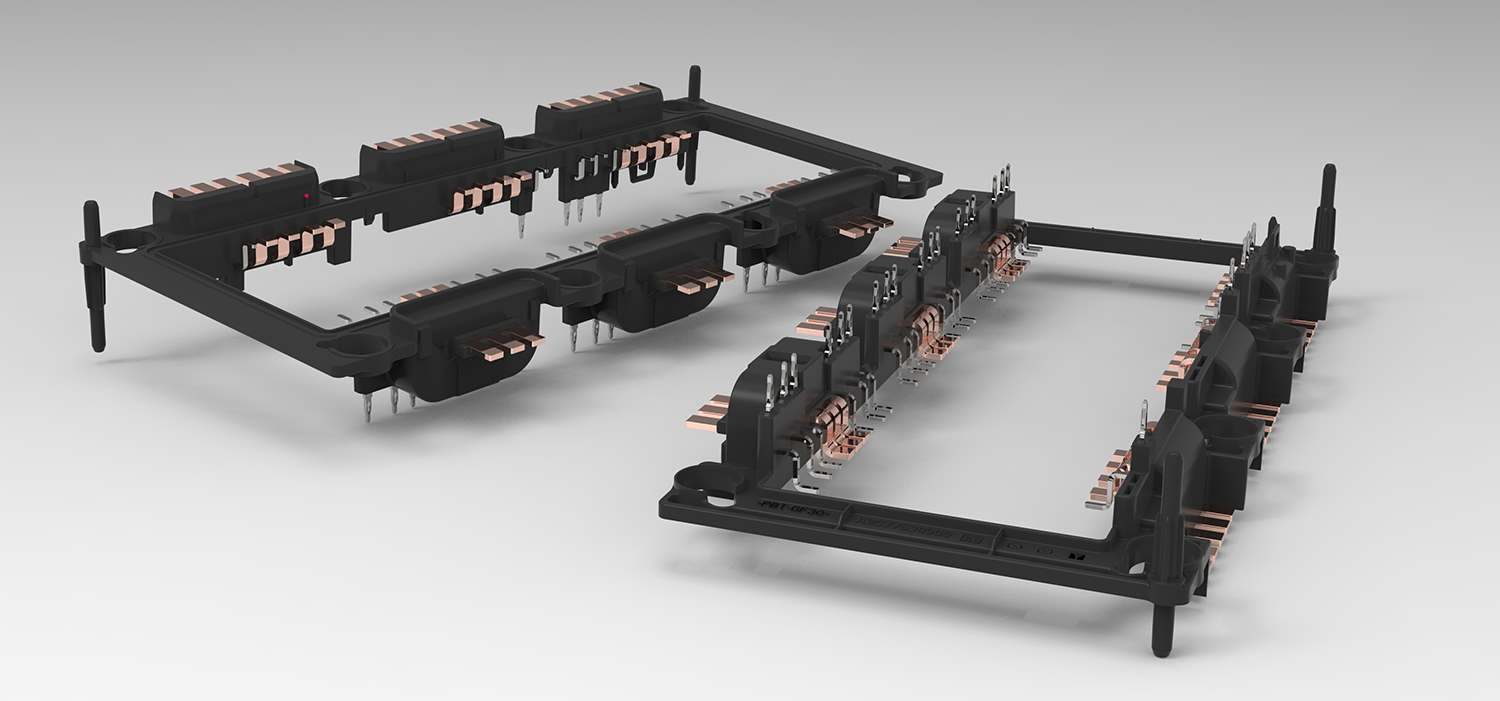

Mechatronics Components

Mechatronics integrates connector functionality and electromechanical components into a higher-level subassembly. Nowadays, most of conventional automotive mechanical equipment have changed to mechatronics system with high content of electronics and high power requirement. New systems for eMobility emphasized these requirement and increased complexity of connectors systems.

- Multiple stamping & plating options

- Multiple sealing solutions

- High performance plastics processing

- Power connection systems for harness interface

- Multiple termination technology for PCB

- Connection technology for busbars

KYOCERA AVX Products Features & Benefits:

- HEV Hybrid Power Control

- Power Distribution

- ACDC & DCDC Converters

- Electrical Power Steering (EPS)

Automotive Applications:

RESOURCES