Radiation Tolerance of Tantalum and Ceramic Capacitors

The radiation hardness of passive electronic components is not currently a well-studied subject, and, in general, they are either considered non-sensitive to ionizing environments or not used in radiation-hardened applications. This lack of knowledge slows the adoption of relatively new technologies in space, nuclear, military, and other applications with ionizing radiation environments, including polymer tantalum capacitors, which offer high energy density, low series resistance, and stable electrical parameters.

To further investigate passive electronic components for these applications, it is important to focus not only on the ionizing radiation dose but also on the type of radiation. The effects of directly ionizing and indirectly ionizing radiation can differ, and each group has further classifications. Directly ionizing radiation consists of charged particles, for example, electrons and protons, with sufficient energy to create ionization in materials. Due to their charge, they are influenced by electromagnetic fields, generally reducing their penetrability. Indirectly ionizing radiation includes particles without electrical charge, such as neutrons and photons, and has higher penetrability due to a lower probability of interaction with matter.

In a 2023 article titled Radiation Tolerance of Tantalum Polymer Capacitors, Kyocera AVX investigated the radiation tolerance of molded SMD tantalum capacitors with both conventional MnO₂ cathode and polymer cathode. In both cases, the capacitors showed excellent radiation tolerance in terms of capacitance (CAP), dissipation factor (DF), equivalent series resistance (ESR), and direct current leakage (DCL) after irradiation with a 20 MeV photon beam at a dose rate of 1.44 kGy, up to a total dose of 4.5 kGy [1].

This article further investigates the radiation tolerance of passive components across multiple high-reliability capacitor series manufactured by Kyocera AVX, specifically the hermetically sealed polymer tantalum capacitors, MIL-PRF-39006/33 wet tantalum capacitors, and MIL-PRF-32535 MLCCs with X7R dielectric.

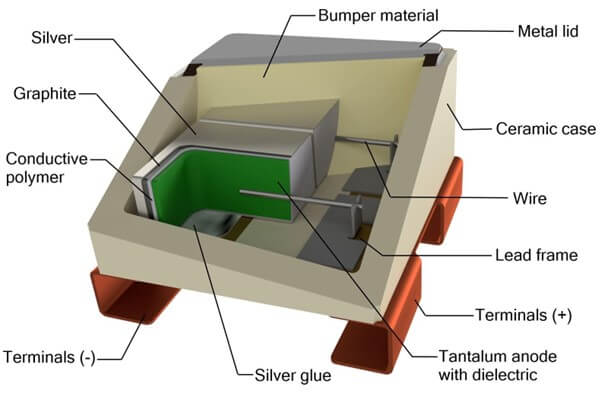

The construction of hermetically sealed tantalum capacitors is similar to that of standard SMD polymer tantalum capacitors, as shown in Figure 1. Each capacitor consists of a sintered pellet of tantalum powder with a very high surface area. The tantalum pentoxide dielectric is formed by applying DC voltage to pellets submerged in an acidic electrolyte, with dielectric thickness proportional to the applied voltage. The polymer cathode terminal is prepared either by in-situ polymerization or by depositing polymer dispersions. The most commonly used conductive polymer material is PEDOT (poly(3,4-ethylenedioxythiophene)), which provides strong contact with the dielectric, high conductivity, and temperature stability. Hermetically sealing these capacitors in a ceramic case prevents oxidation and humidity degradation of the polymer cathode.

Hermetically sealed polymer tantalum capacitors offer low ESR, high energy density, voltages up to 125 V, and stable electrical parameters. Typical applications include power supplies and pulse power in aerospace and defense. [2,3]

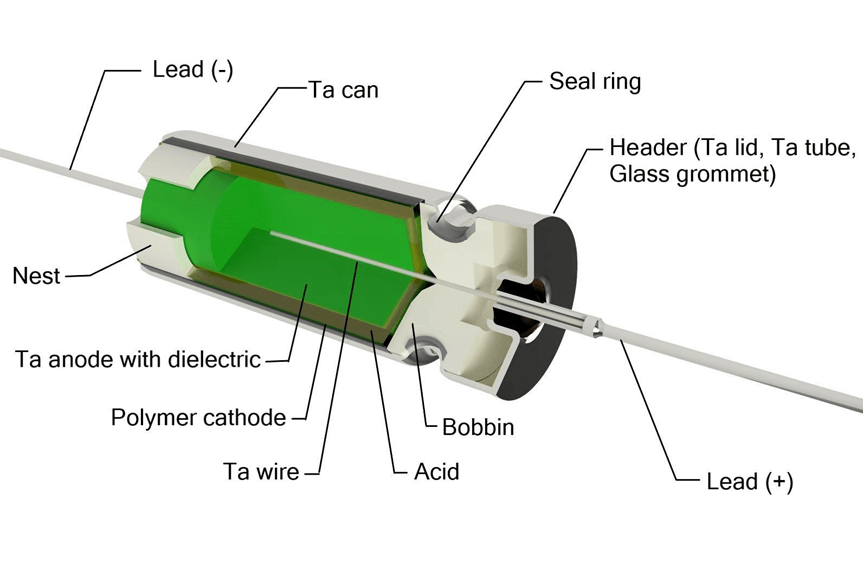

Similar to SMD polymer tantalum capacitors, wet tantalum capacitors consist of a sintered pellet made from pressed tantalum powder with a very high surface area and an embedded tantalum wire. This pellet serves as the positive electrode (the anode). A layer of tantalum pentoxide (Ta₂O₅) dielectric is created on the anode surface by applying a DC current across the anode in an acidic electrolyte. The negative electrode (cathode) includes an extremely high surface area material on the inner surface of a tantalum can, which is in contact with a liquid electrolyte. This electrolyte connects the cathode to the dielectric layer, forming the complete cathode. All components are contained within the can, which is hermetically sealed, with an external anode lead connected to the embedded anode wire and an external cathode lead connected to the can. An example is shown in Figure 2.

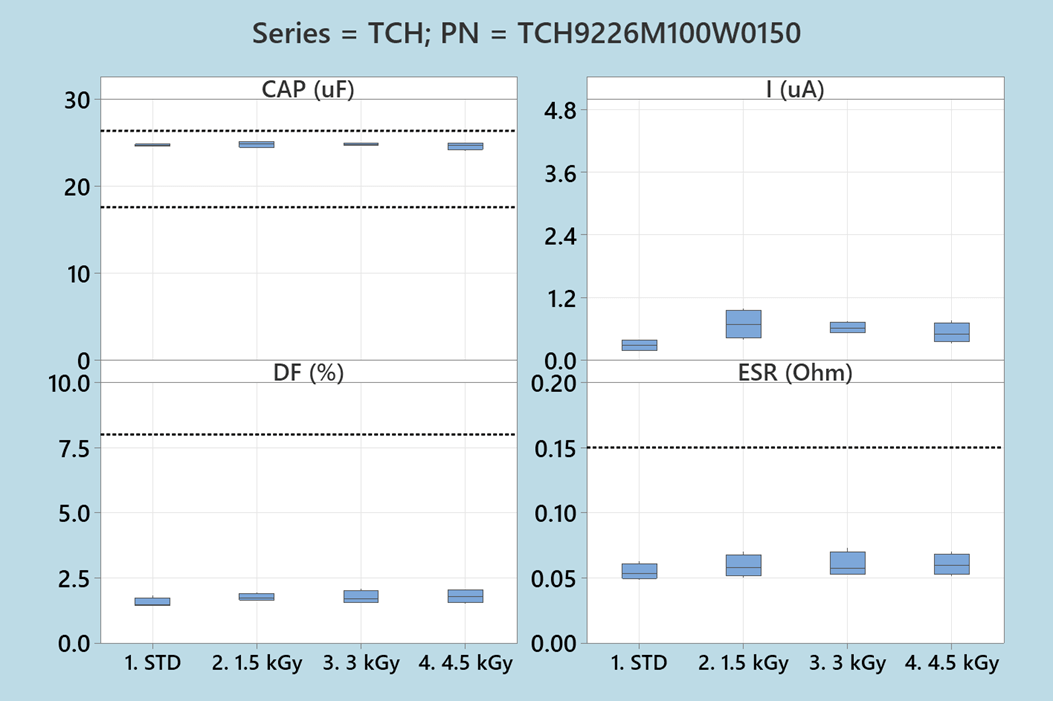

Wet tantalum capacitors have been used for many years in high-energy storage applications where volumetric efficiency and high reliability are essential, including in industrial petroleum exploration, military avionics, and aerospace applications [4]. The Kyocera AVX MIL- PRF-39006/33 meets the requirements for wet tantalum capacitors in military applications.

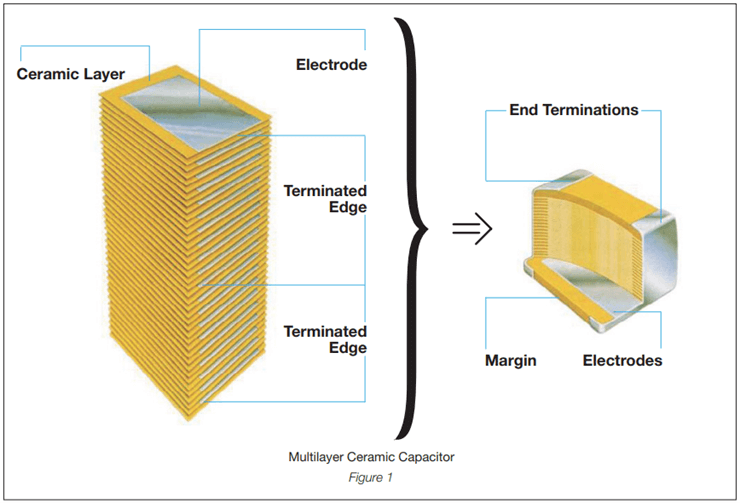

Multilayer ceramic capacitors (MLCCs) consist of a monolithic ceramic block containing two sets of offset, interleaved electrodes embedded within the ceramic dielectric. Two types of ceramic formulations are commonly used: Class I, which is temperature-compensating, and Class II, which is temperature-stable and suitable for general applications. The X7R dielectric is one of the most widely used Class II formulations, known for its capacitance variation within ±15% over a temperature range of -55°C to +125°C. In addition to temperature, the capacitance of Class II MLCCs varies with applied voltage and frequency (for more details on performance under various operating conditions, consult Kyocera AVX’s SpiCap software). [5] An example of MLCC construction is shown in Figure 3.

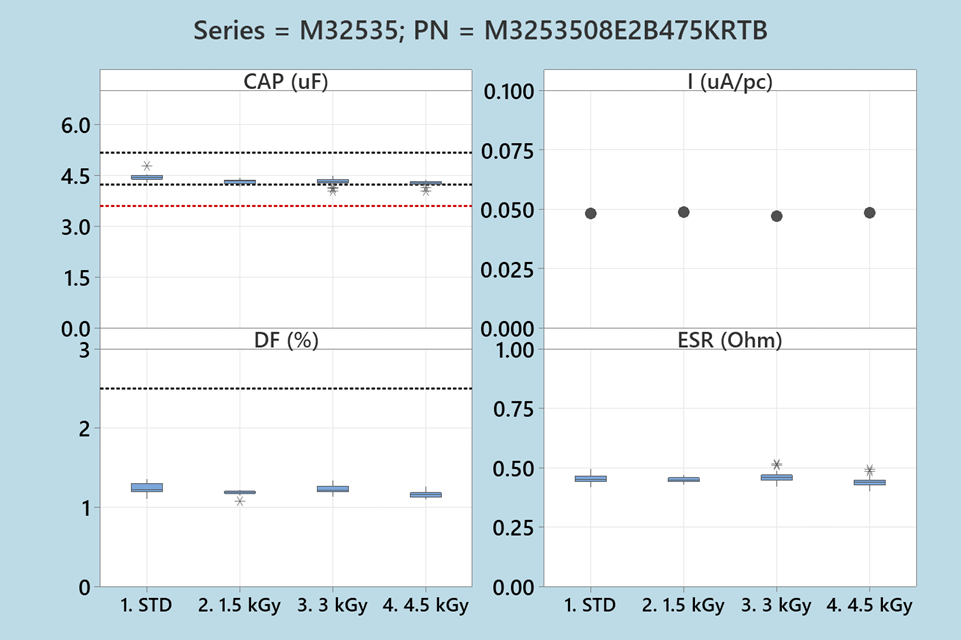

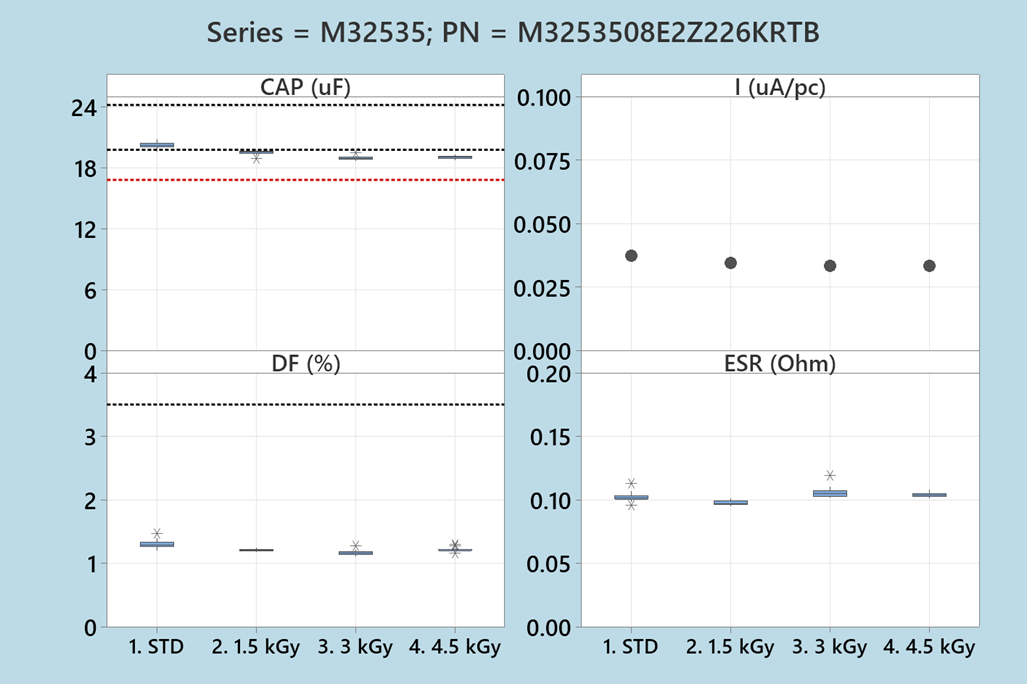

Kyocera AVX offers DLA-approved MIL-PRF-32535 X7R dielectric MLCCs in case sizes from 0402 to 2220, with capacitance/voltage ratings ranging from 2.2 nF to 22 µF and 16 to 100 V. These capacitors expand the CV range compared to standard MIL specifications while maintaining high reliability. Typical applications include science exploration satellites, earth observation satellites, communication satellites, satellite launchers, and various military and land or air-based applications. [6]

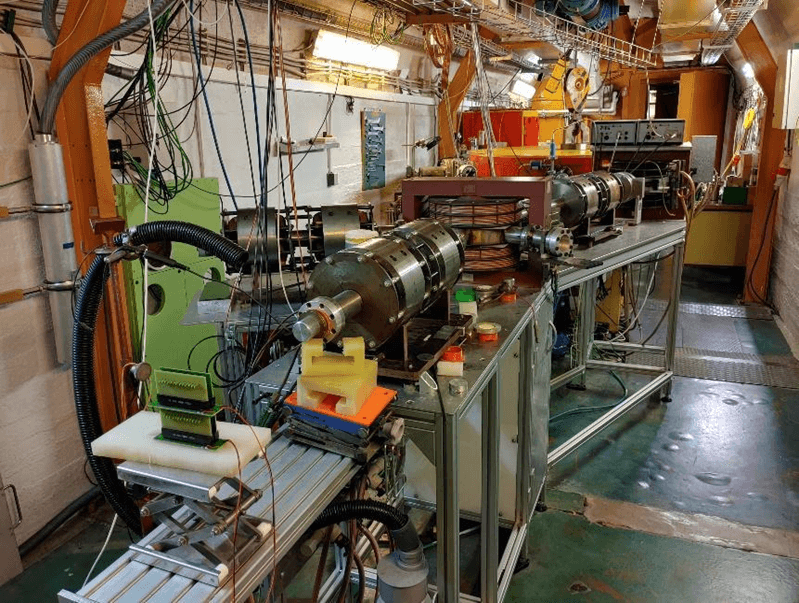

For the irradiation of parts, a Microtron MT25 was operated by the Czech Academy of Sciences (CAS) in Prague (Figure 4).

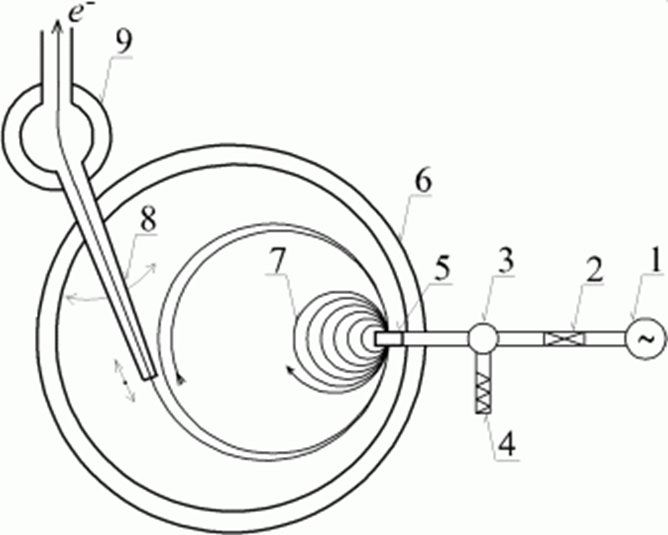

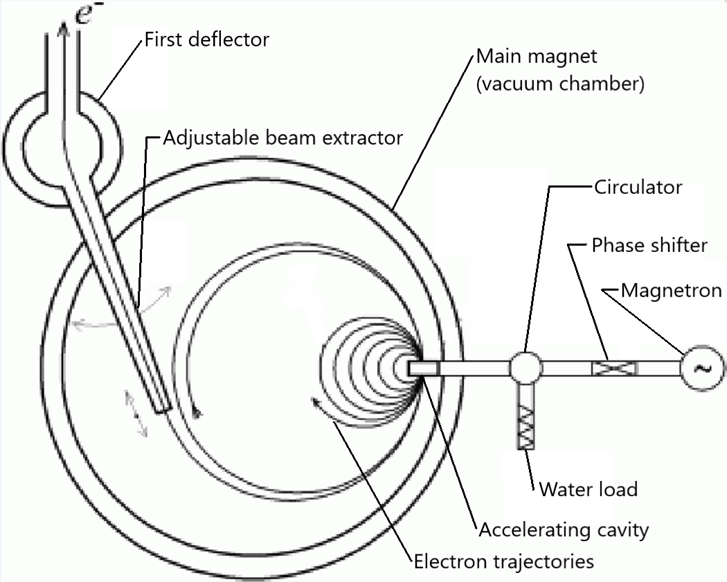

The MT25 is a cyclic electron accelerator with a Kapitza resonator, capable of energizing electrons in clusters at levels scaled by 1 MeV steps from 6 MeV to 25 MeV. The electrons are accelerated by an RF electric field of constant amplitude and frequency, in a uniform magnetic field. A schematic of the MT25 is shown in Figure 5. [7]

Unlike cyclotrons that produce protons, the microtron accelerates electrons, which are approximately one thousand times lighter than protons. Although electrons can be accelerated to high kinetic energies comparable to protons, their interactions with matter differ significantly due to differences in mass, charge, and behavior at the atomic level. The lower mass of electrons results in lower imparted energy on irradiated samples, primarily causing chemical changes without inducing nuclear reactions. Consequently, no radioactivity is imparted onto the device under test (DUT), making it easier to achieve homogeneous irradiation of the sample. The microtron also provides excellent control and configurability of the total radiation dose. [1]

The irradiation used a photon beam (Bremsstrahlung) with an energy of 20 MeV. This electromagnetic radiation is produced by the deceleration of electrons passing through a tungsten target placed behind the exit window.[7] The dose rate of this photon beam was 1.44 kGy/hour.

The extreme irradiation dose used an electron beam directly from the microtron, with an energy of 20 MeV and a dose rate of 120 kGy/hour.

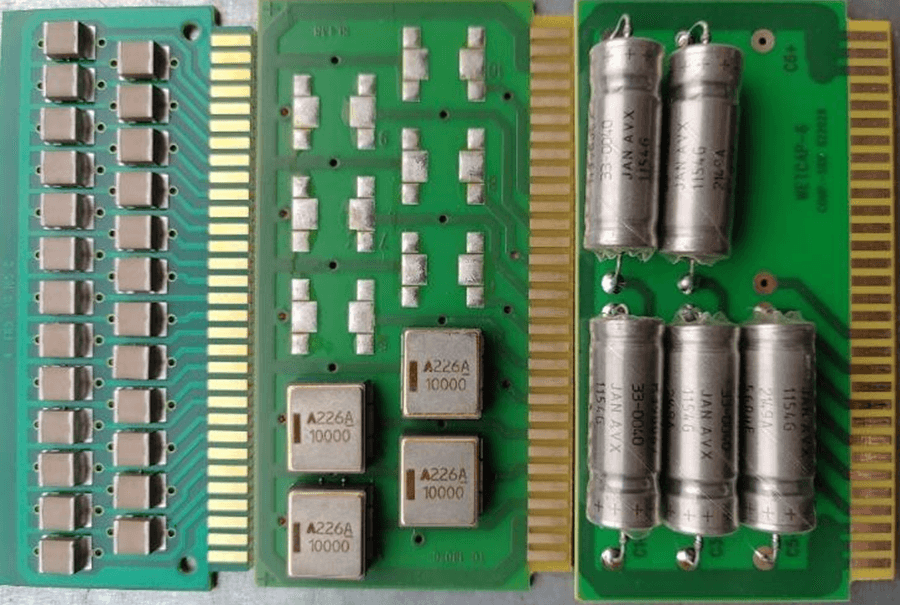

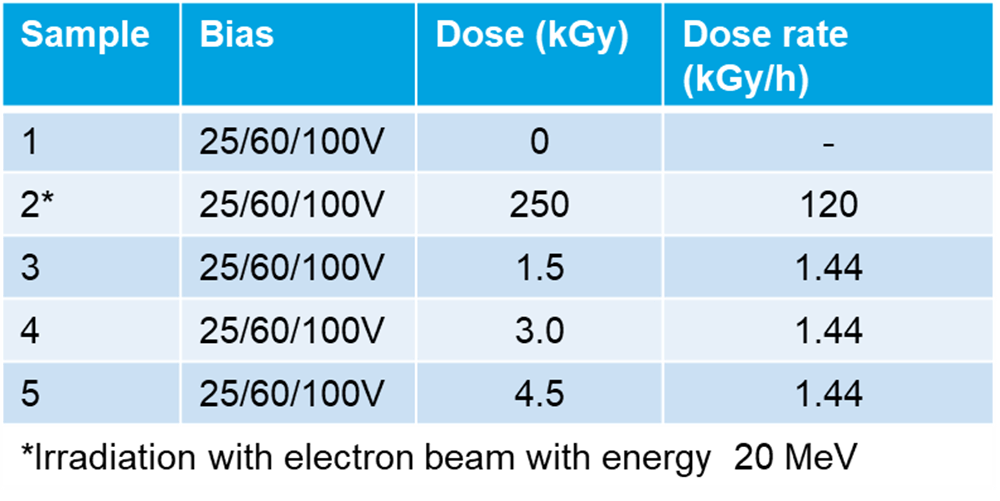

The hermetically sealed tantalum polymer capacitors (TCH9226M100W0150), wet tantalum capacitors (M39006/33-0040), and two ceramic capacitors with X7R dielectric were mounted on a custom FR5 PCB array for irradiation and characterization (Figure 6). Each group was exposed to three different radiation doses from a photon beam while the rated bias voltage was applied. Additionally, all groups were tested with an extreme irradiation dose from the electron beam, with the rated bias voltage applied, as shown in Figure 7.

In addition, a 24-hour, 125°C high-temperature annealing period was included as the final stage in the testing cycle. This step, commonly referenced in standards for irradiated components (such as MIL-STD 750-1, MIL-STD 883, ESCC 25100, and ESCC 22900), may help dissipate excitation electrons induced in the dielectric material by radiation.

After each radiation dose, the bulk capacitance, ESR, dissipation factor (DF), and DC leakage current (DCL) were measured across the devices in the array. For hermetically sealed polymer tantalum capacitors, bulk capacitance and DF were measured at 120 Hz with a 2 V bias and a 1 V AC measurement current; ESR was measured at 100 kHz with a 2 V bias and a 1 V AC measurement current; and DCL was measured with a 1 kΩ resistor in series at room temperature (RT), with readings taken after 300 seconds of applying the rated voltage.

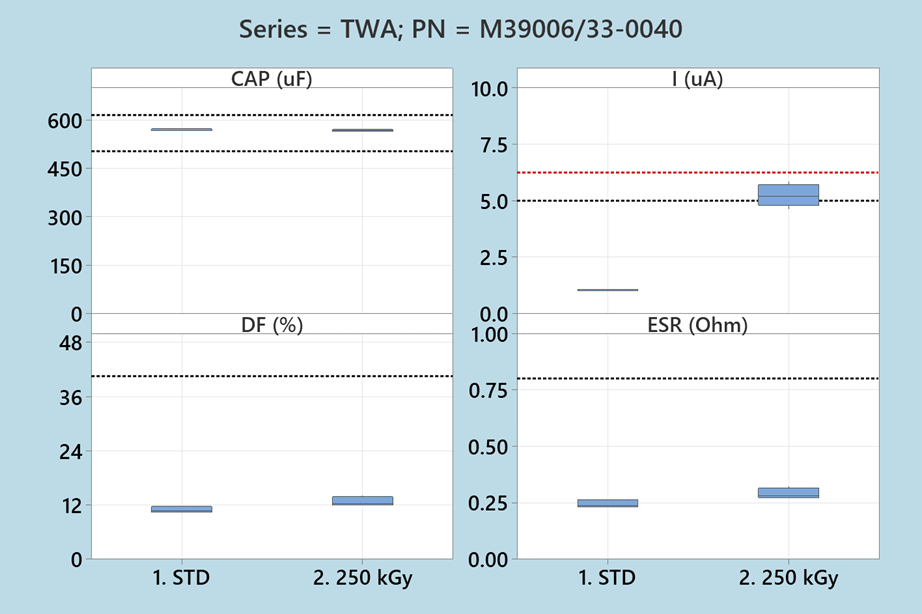

For wet tantalum capacitors, bulk capacitance, DF, and ESR were measured at 120 Hz with a 2 V bias and a 1 V AC measurement current; DCL was measured with a 1 kΩ resistor in series at RT, with readings taken after 300 seconds of applying the rated voltage.

For ceramic capacitors with X7R dielectric, bulk capacitance, DF, and ESR were measured at 1 kHz with a 2 V bias and a 0.5 V AC measurement current; DCL was measured with a 10 kΩ resistor in series at RT, with readings taken after 300 seconds of applying the rated voltage.

By observing changes in these parameters across different radiation doses, the resilience of each device under ionizing radiation can be assessed.

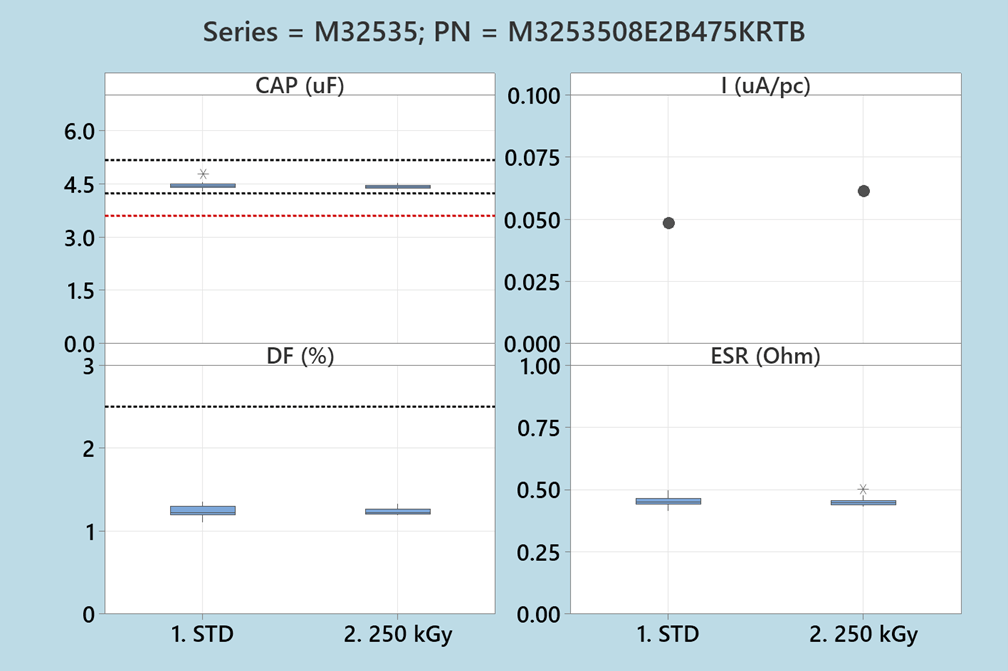

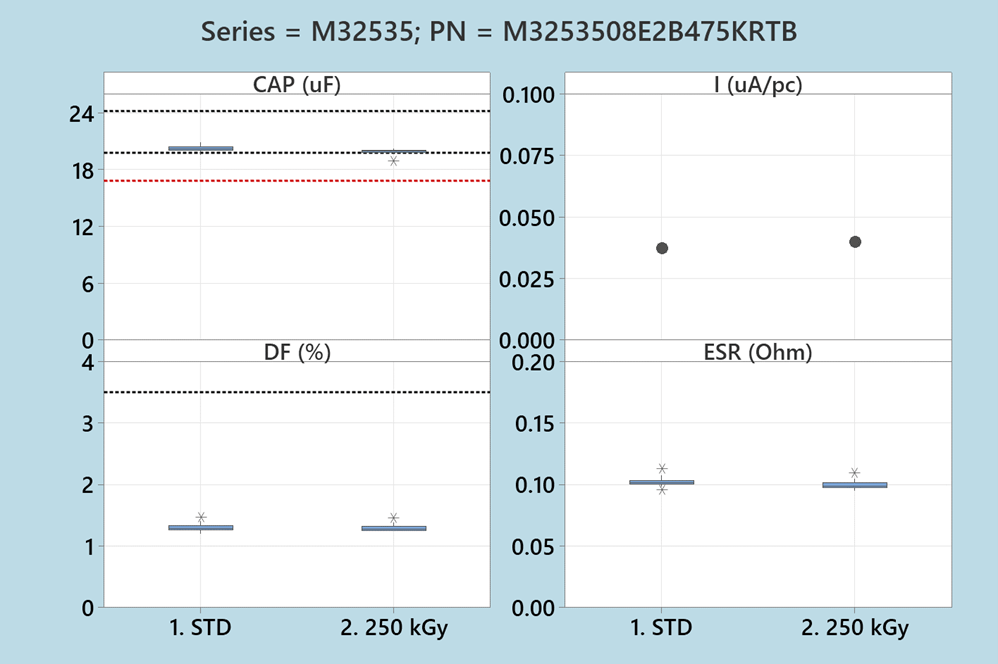

A slight decrease in capacitance was observed for both the 25 V and 100 V MLCCs after photon irradiation at doses ranging from 1.5 to 4.5 kGy (Figures 8 and 9). The capacitance change after irradiation was -7.5% for the 100 V parts and -10% for the 25 V parts. For both part numbers, the capacitance remained within the permitted -15% change specified in MIL-PRF-32535 (red line), despite the decrease.

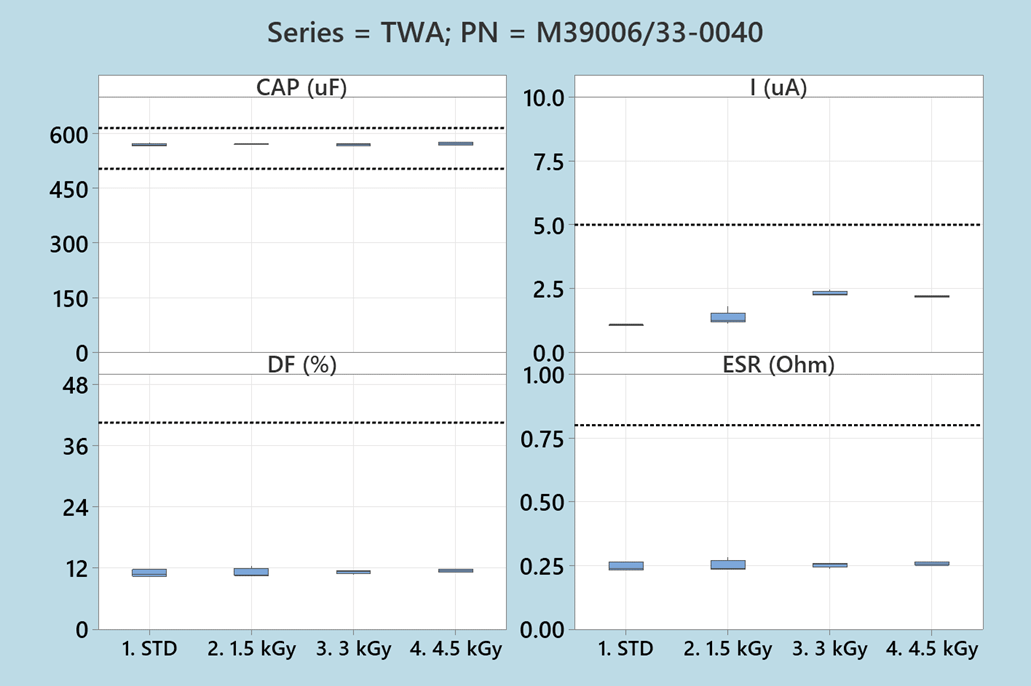

A slight increase in leakage current was noted in the wet tantalum capacitors, rising by approximately 1 µA to a total of around 2 µA (Figure 11). This increase had no relevant impact on the performance of the parts and remained well below the 5 µA specification limit (black line).

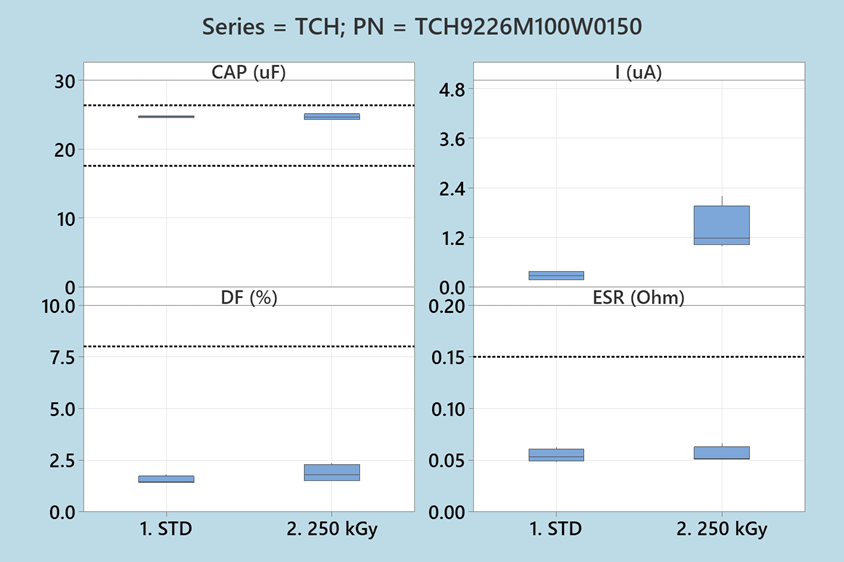

No other significant changes were observed in the measured parameters for any of the tested capacitors following photon beam irradiation at doses up to 4.5 kGy. The hermetically sealed polymer tantalum capacitors exhibited excellent stability across all measured parameters under photon beam irradiation up to this dose level (Figure 10).

Electron beam irradiation at a dose of 250 kGy caused an increase in DCL across all tested capacitors. The DCL of both MLCC part numbers remained below 70 nA after testing (Figures 12 and 13).

In the hermetically sealed polymer tantalum capacitors, DCL increased by approximately 1 µA. Following testing, the DCL remained within the specification limit of 220 µA for these parts (Figure 14).

For the wet tantalum capacitors, the highest observed DCL increase from electron beam irradiation was from 1 µA to 5.1 µA, with some parts exceeding the initial specification limit of 5 µA. According to MIL-PRF-39006/33B, an increase of up to 125% of the initial DCL limit is permissible for reliability tests, which equates to 6.25 µA for this part number; this threshold was not exceeded (Figure 15).

The X7R dielectric MLCCs exhibited a decrease in capacitance after photon beam irradiation at doses up to 4.5 kGy and electron beam irradiation at a dose of 250 kGy; however, this decrease remained within reliability testing limits. Additionally, DCL showed a negligible increase under electron beam irradiation. The ESR and DF parameters demonstrated excellent stability under these conditions. These results align with findings in previous publications [8], supporting the recommendation of these capacitors for military and space applications with radiation exposure.

The hermetically sealed tantalum capacitors demonstrated excellent radiation stability across all electrical parameters following photon beam irradiation at doses up to 4.5 kGy and electron beam irradiation at 250 kGy. This behavior is consistent with that of molded SMD tantalum polymer capacitors [1]. The combination of high volumetric efficiency, low ESR, and long lifetime with self-healing properties makes these capacitors suitable for military and space applications with radiation exposure.

The wet tantalum capacitors also showed excellent stability in electrical parameters after photon beam irradiation at doses up to 4.5 kGy. Following electron beam irradiation at 250 kGy, DCL slightly increased but remained within reliability testing limits. Based on these results, wet tantalum capacitors are recommended for military and space applications with radiation exposure.

The observed DCL changes following the extreme 250 kGy electron beam dose were attributed to the direct ionizing effect of electron irradiation and its high energy density, with a dose rate of 120 kGy/hour.

Future testing could explore real-time measurement of electrical parameters for conventional MnO₂ tantalum, polymer tantalum, and wet tantalum capacitors during irradiation, as well as studying the effects of neutron irradiation. Both tests present unique challenges in terms of testing equipment and radiation safety.

To learn more about KYOCERA AVX’s tantalum polymer capacitors, visit: https://www.kyocera-avx.com/products/tantalum/high-reliability/

References:

- [1] K. Adamek: Radiation Tolerance of Tantalum Polymer Capacitors. (2023)

- [2] J. Petrzilek, M. Uher, J. Navratil, M. Biler: Polymer Tantalum Capacitors for Advanced High Reliability Applications, SPCD (2016)

- [3] KYOCERA AVX Provided Key Components for the Historic Chandrayaan-3 Lunar Mission. (n.d.). Kyocera AVX. Retrieved August 29, 2024, from https://www.kyocera-avx.com/news/chandrayaan-3-lunar-mission/

- [4] Tantalum WetElectrolytic Capacitors Guide. (n.d.). Kyocera AVX. Retrieved August 29, 2024, from https://www.kyocera-avx.com/docs/techinfo/WetTantalum.pdf

- [5] Surface Mount Ceramic Capacitor Products. (n.d.). Kyocera AVX. Retrieved August 29, 2024, from https://catalogs.kyocera-avx.com/SurfaceMount.pdf

- [6] MIL-PRF-32535 X7R BME Multi-Layer Ceramic Capacitors (MLCC). Kyocera AVX. Retrieved August 29, 2024, from https://www.kyocera-avx.com/products/ceramic-capacitors/surface-mount/militaryaerospace/mil-prf-32535-x7r-bme-mlcc-ceramic-capacitors/

- [7] Microtron MT25. (n.d.). Ústav jaderné fyziky AV ČR. Retrieved November 13, 2022, from http://www.ujf.cas.cz/en/departments/department-of-accelerators/microtron/

- [8] C.L. Hanks, D.J. Hamman: Radiation Effects Design Handbook Section 3. Electrical Insulating Materials and Capacitors. NASA CR-1787. (1971)